We identified possibilities for annual savings of up to EUR 2.60 million

We reduced changeover times from 320 to 168 minutes

We identified opportunities to increase capacity utilization by 14%

Our OpEx team was commissioned by a large hygienic paper manufacturer to improve productivity. Poor utilization of machine and human resources, ineffective recruitment processes, and inappropriate motivation schemes resulted in unnecessarily high costs, working capital, and an adverse impact on EBITDA.

Thanks to the understanding between the parties and the expertise of our OpEx team, we identified opportunities, and proposed the approach, methods, and objectives for a productivity improvement project to reduce waste, increase resource utilization, throughput, and EBITDA.

Our approach

To understand the existing process, map the current status of production, waste, and supporting functions, and identify improvement opportunities, the OpEx team conducted and presented the following studies and analyses:

- assessment of production, quality, the supply chain, and maintenance using statistical, operational, and qualitative studies;

- OEE (Overall Equipment Effectiveness)

- shop-floor studies evaluating processes and the use of resources;

- DILO (Day in Life of Operator);

- various tools for mapping processes;

- impactibility workshops;

- matrix of roles and responsibilities; and

- implementation plan for certain parts.

Detailed implementation plan

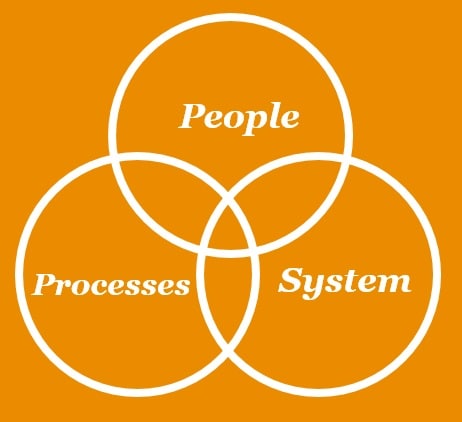

After less than six weeks, we presented the client with a complex analysis of production, planning, and management of the product portfolio and supporting activities. We identified problems and inefficiencies and agreed on their elimination with the client’s staff. Solutions were suggested comprehensively to cover process-related and human elements. Special focus was placed on activities to reduce waste, increase the utilization of machines and equipment, reduce the amount of slow-moving stock, improve the accuracy of planning, and reduce absences and staff overtime.

Our client appreciated the engagement of its staff in the preparation of solutions from the beginning and their stronger sense of responsibility for the achieved results.

Contact us