Life Cycle Assessment

How do we measure a product’s environmental impact? And how can we say which products are more/less impactful than others?

We can answer these questions and many more by using a Life Cycle Assessment (LCA). This method assesses environmental impacts associated with all the stages of a product's life cycle, including raw material extraction and material processing, manufacture, distribution, use and end-of-life. A holistic point of view is adopted to assess the environmental impact of a product.

There are several ways an LCA can be undertaken:

Cradle-to-gate: impact is measured only from the point of raw material extraction to the point when the product is ready to leave the manufacturer’s gates.

Cradle-to-grave: impact is measured from the point of raw material extraction to the point when the product has finished its useful life.

Cradle-to-cradle: impact is measured from the point of raw material extraction to the point when the product is recycled or reused and starts a new life cycle.

The method is standardised and guided by ISO 14044:2006, which makes the results comparable globally and across products.

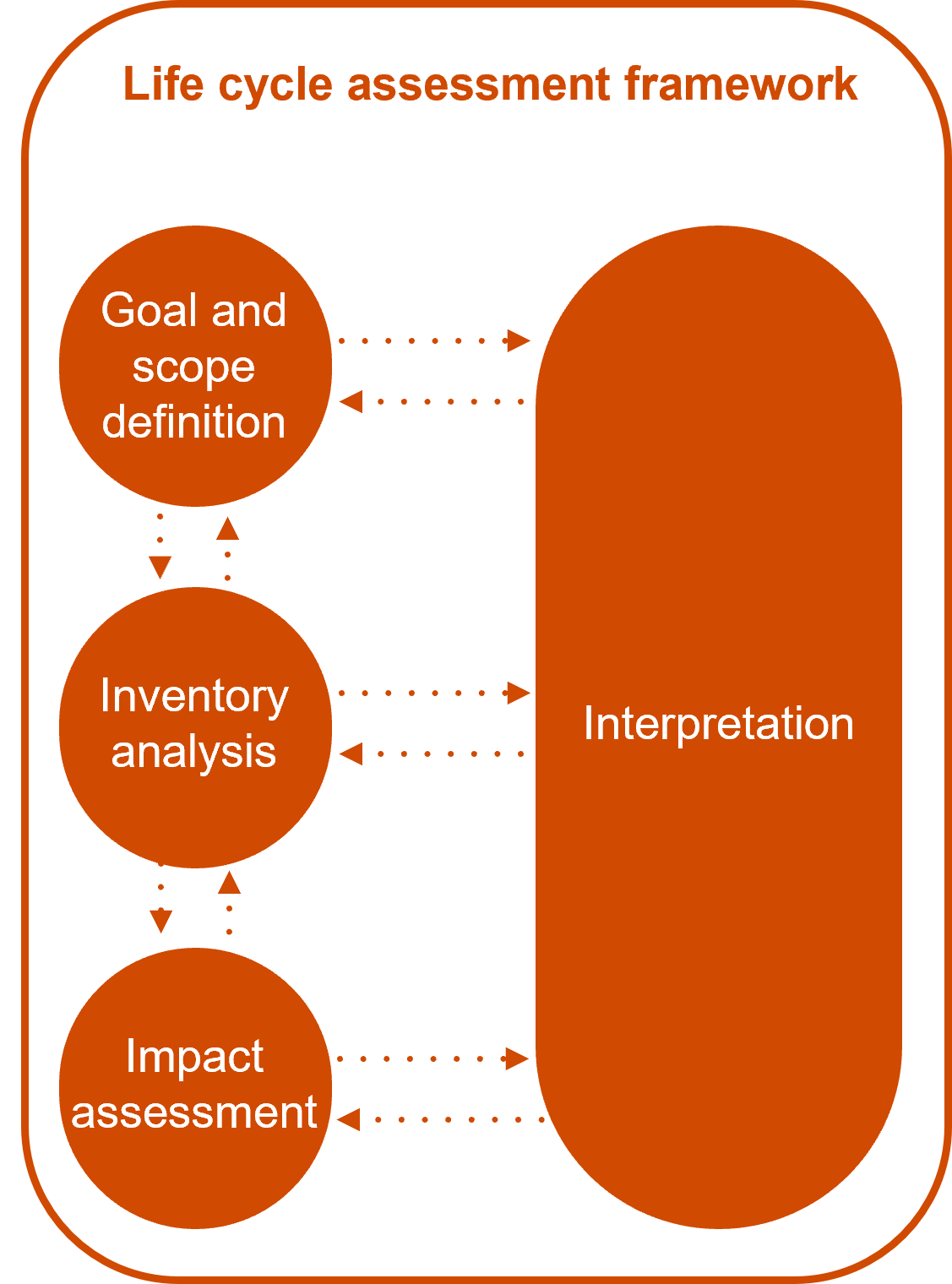

According to the standard, an LCA should consist of the following stages:

Muralikrishna,I. V., Manickam, V. (2017) ‘Life Cycle Assessment’ in Environmental Management. Butterworth-Heinemann, pp. 57-75.

In the beginning, the goal and scope of the study are defined, followed by the inputs and outputs analysis for each process (inventory analysis) which is needed to produce a product. After collecting all the information on inputs and outputs, the product’s environment impact is assessed. This is based on several impact categories including:

Global warming potential (i.e. carbon footprint)

Cumulative energy demand

Water use

Resource depletion

Acidification (causes acid rain)

The choice of the impact categories depends on the method of assessment selected and the nature of the product.

Therefore, an LCA is a more complex evaluation of the environmental impact of a product, as it takes into consideration many more aspects of the product than just its GHG emissions. It may happen that a product can perform well as regards global warming potential, but it consumes too much water over its life cycle.

An LCA can be used to identify so-called “hotspots” in the life cycle indicating where the company or its suppliers can adapt their processes to decrease their environmental impact. An LCA can thus be used for learning about your own supply chain and its impact and for informed decision making to reduce your environmental impact. In the past, for example, companies used LCA results for their products to change their transportation mode for the required raw materials to reduce their carbon footprint. Another company changed its coating material, so its product became biodegradable and did not need to be incinerated. In addition, the company’s global warming potential and acidification decreased, making it more competitive compared with its counterparts. LCAs are used to aid the decision-making process when companies don’t know what would have the greatest impact when they want to reduce the environmental footprint of their products. An LCA allows companies to test different options, find hotspots and the desired leverage point(s).

Thus, if you really want to know what could be more sustainable, we recommend carrying out a life cycle assessment of your product.

PwC Slovakia can help you with:

Setting the goal and scope of your assessment

Collecting data for a life cycle inventory

Assessing the environmental impact based on the data

Choosing the right assessment method

Data interpretation

Preparation of an LCA report

Subscribe to our PwC Newsletters

Contact us